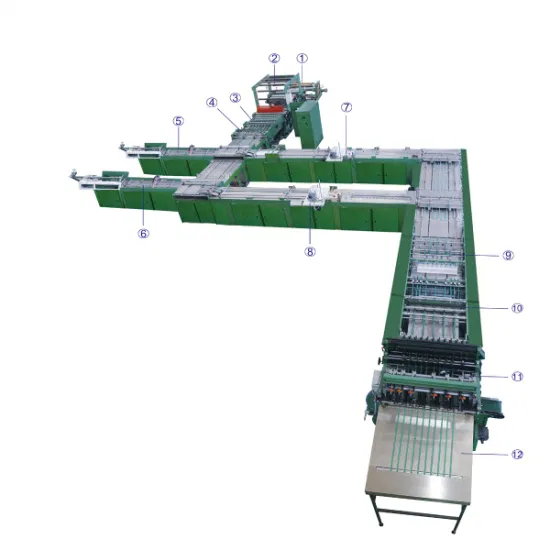

Thread Sewing Notebook Machine Reel to Product

Thread sewing notebook machine reel to product This machine utilizes advanced technology such as microcomputer controls,

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | LD1050AX |

| Production Scope | Product Line |

| Process | Sewing Notebook |

| Automatic | Full Automatic |

| Model | Ld-1050ax |

| Machine Color | Green, Grey, White |

| Binding Way | Thread Sewing |

| Usage | Making Thread Sewing Exercise Book |

| Machine Weight | 26ton |

| Transport Package | Wooden Cases |

| Specification | A3, A4, B5, A5 etc |

| Trademark | LianDong |

| Origin | China |

| HS Code | 8441100000 |

| Production Capacity | 50 PCS/ Year |

Product Description

Thread sewing notebook machine reel to productThis machine utilizes advanced technology such as microcomputer controls, photoelectric tracking, touch screen operation and water ink flexographic printing etc. This production line is fully automatic, very easy to operate. Needing 5-7 persons in total. It features a matched combination of reel stand, high speed 2/2 flexographic printing, sheet cutting, counting, title page insertion, two groups of sewing units, paper cover gluing and insertion, folding, pressing, 3-side cutting and product collection. This equipment is an ideal choice of mass production of thread sewing exercise books.

| NO. | Product Model | LD-1050AX |

| 1 | Web Width | 580-1050mm |

| 2 | Max. Printing Speed | 200m/Min |

| 3 | Rotary Slitting Length | 297-600mm |

| 4 | Counting & Collating | 8-30 Sheet |

| 5 | Max Reel Paper Diameter | 1200mm |

| 6 | Sheet Weight | 45-100g |

| 7 | Cover Weight | 120-350g |

| 8 | Title Page Weight | 70-150g |

| 9 | Max.Sewing Speed | 40times/minute |

| 10 | Max. Cutting Speed | 50times/minute |

| 11 | Main Motor Power | 30kw |

| 12 | Overall Dimensions (L X W X H ) | 17000 X 8000 X 2400mm |

| 13 | Machine Weight | 26ton |